An end-to-end factory solution for all your machine vision needs

Set up Meeting with UsFlexible Vision is an AI machine vision software and hardware application that works together to streamline visual inspections on the factory floor. We understand that all businesses need quality control, but traditional camera systems can’t solve the problem effectively.

Similarly, operators doing manual inspection is expensive and inefficient. After visual inspection, the cloud portal stores data so your teams can collaborate and share visual inspection programs across factory floors.

It’s never been easier to stay on top of your business’s needs.Our software seamlessly collects a series of 5-10 images, documenting both good and bad product inspections. The sample size can be optionally increased with augmentation, allowing your team to target issues and successes in one place.

Image tagging makes it simple to organize and locate your factory images. By using our cloud-based UI, you can tag images with the areas of interest. This makes it efficient to share and collaborate on different image types.

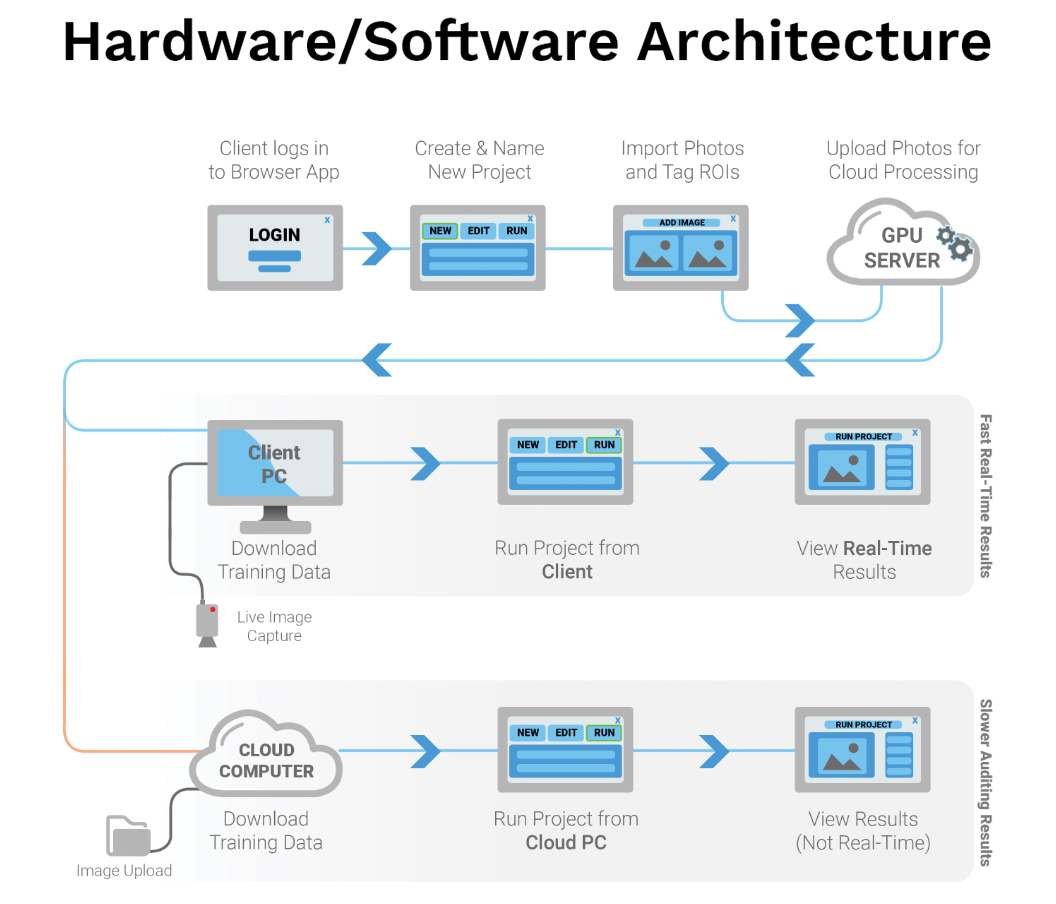

A deep learning model will give you a comprehensive glimpse into your project, automatically storing it in the cloud for easy access. With the click of a button, your model will be created and ready for production in minutes.

After creation, your AI model will automatically deploy and prepare for validation. At this stage, you can download and sync your model to as many on-premise production lines as necessary. Our cloud-based software makes it simple to add production lines later on if needed.

Image storing is an advantageous feature that gives you a trackable and traceable timeline of your product. In case of error or recall, you can reference your cloud folder. All images will automatically sync to your cloud storage account. If you need to locate a file, you can search for images by date, time or serial number.

Our software allows for constant growth and progress as it evolves with your business needs. As your system collects more images, you may find new inspection criteria along the way. All of these images can automatically be included in your next model.

Please send your query or requirements in detail via whatsapp, and we will respond shortly.

Thank you!